Customer satisfaction drives your automotive business, between referrals and repeat business. One of the best ways to keep car owners satisfied is with preventative maintenance, eliminating the potential for problems before they happen. And since approximately 20% of vehicles on the road today have a bad or failing battery, it makes sense to identify the problem when they come in for service, whether it’s a primary complaint of theirs or not.

However, testing every vehicle’s battery when it’s in the shop can be a target that’s more complicated to achieve than it first appears. And when the test is done, moving from the diagnosis to the sale can be tricky. Your shop’s customer satisfaction depends partially on ensuring that you can move past the common challenges of battery testing. Here are five areas to consider.

Converting to a Sale

“I haven’t had a problem starting my car.”

“Why did you test my battery? I didn’t ask you to.”

“Your batteries are overpriced. I’m going to go elsewhere.”

These and other obstacles pop up regularly for service advisors that present customers with failed battery test results. It seems that performing a battery test isn’t always viewed as a proactive, preventative measure that the service shop uses to better service their customers’ vehicles. So, when car owners see a quote for a replacement battery, getting defensive can be a default reaction.

In many instances, the objections are based on one thing: the vehicle owner was unaware their car’s battery would be tested. They become wary, and it can affect their receptiveness to other necessary repairs and services on that visit and subsequent visits.

However, if the service advisor lets them know at check-in that their battery condition will be tested and they’ll receive a report, it prevents them from building a wall in the first place. The likelihood of moving to the sale when presented with an estimate for a new battery grows, as does their appreciation for their mechanic doing “the little things”, like testing car batteries on every vehicle.

Of course, there are other issues like pricing to get past, and being armed with comparison shopping data from local competitors is a great way to do just that.

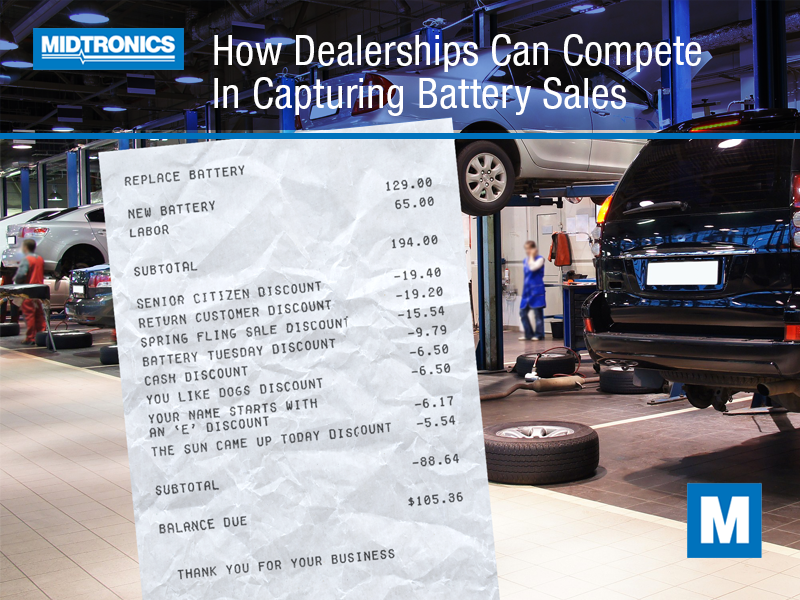

Following Up On Failed Tests

It would be incredible to sell batteries to even one in ten customers that pass through the service doors, never mind one in five, but that’s not a realistic expectation. Some of those vehicle owners aren’t prepared time-wise, mentally, or financially at that exact moment to spend a few hundred dollars on a new battery. Instead, some will replace the battery themselves while others will go elsewhere, unfortunately, like a big box store that undercuts pricing just to get customers in the door.

But some owners simply weren’t prepared in that moment and would be willing to trust your shop for a new battery – you just need to ask again. After a battery test has failed, it should be trackable so someone in your service department or call center can reach out in a day, three days, a week, or even two weeks to see if they’re ready to come back. Following up on declined services is a common process, but a failed battery test needs to be recorded so it can be tracked, which is where some shops fall short.

Accessing a Battery Tester

“Jon, have you seen the battery tester?”

“Kim, do you know how many people are ahead of me for the battery cart?”

“Forget it, I’ll just mark the battery on this MPI form as N/A this time. I can’t keep waiting.”

If your technicians are paid flat rate, there’s an urgency to every vehicle they work on. If a piece of equipment, like a battery tester, is unavailable in the timespan they have the car in their bay, the odds of it getting kicked out without a test grow quickly. It’s an even bigger problem for times like the start of the day when an influx of vehicles has everyone looking for a tester at the same time.

Rather than reduce a tech’s productivity by making them wait for a tester, ensure the instances of an occupied or missing piece of equipment are few and far between. Ideally, one battery tester per four to five general technicians is a good benchmark for a busy shop.

Prioritizing Consistent Testing Practices

And finally, instances of battery tests getting completed on every vehicle that enters the shop will wane from time to time. It could be periods of extreme busyness, a missing staff member, or a lack of emphasis from management on a regular basis. That’s when objections grow, flagrant bad batteries are missed, and it begins to affect customer satisfaction and sales.

Make sure everyone understands the “why” behind testing every battery, and use real examples of what happens when consistent testing practices fall to the wayside.

Summary

There’s really good evidence that encourages testing every battery on every vehicle that enters your service shop, but that doesn’t mean it doesn’t have its challenges to overcome. Ensure that the environment factors into the test, that service advisors are informing customers of the test and reviewing results whether good or bad, and provide enough equipment so there aren’t any good excuses not to test a battery.