It is no surprise that COVID-19 has reduced the amount people drive. Additionally, new car sales have been down, causing vehicles to sit on lots for extended amounts of time. But what is happening to the batteries within those dormant vehicles?

Simply put, when a battery spends prolonged periods of time in a partially to fully discharged state (below 12.4V in many applications is considered partially discharged), it reduces the battery’s overall health and performance capabilities. And with parasitic draws in vehicles, even if the battery was fully charged when you parked it, that battery will become partially discharged over time.

Just because a battery is discharged, doesn’t mean it is bad. It just means it needs to be charged. If it doesn’t accept a charge (charge acceptance), can’t support small loads over time when charged (reserve capacity), or won’t start your car when charged (cranking health); it’s likely a bad battery.

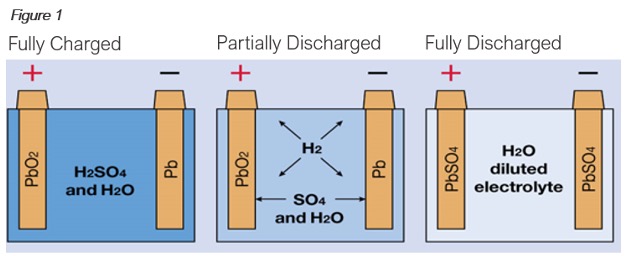

As shown in Figure 1, when the battery is fully charged, it has a healthy mix of sulfuric acid (HS2SO4, or commonly referred to as battery acid) and water (H2O). As the battery gets discharged, the battery acid separates into hydrogen (H2), sulfate (SO4), and water (H2O).

Over time, the heavier sulfate mixture settles and concentrates toward the bottom of the plates. This condition is known as stratification. At this point, the battery will likely lose capacity and experience degraded performance. But with proper battery management, it may be preventable.

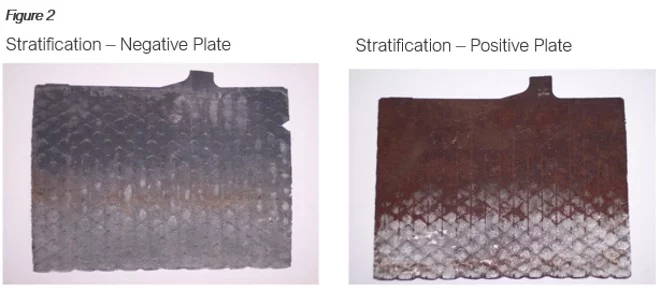

Irreversible damage occurs as the battery sits in this stratified state. When portions of the plates are exposed to a diluted electrolyte for long periods of time, the plates experience corrosion. In Figure 2 you can see the corrosion difference on the top section of the plate vs. the bottom section.

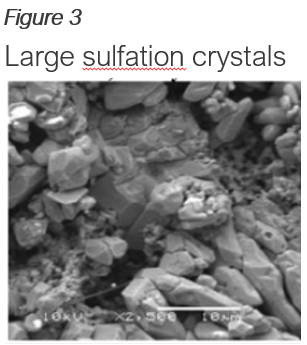

In addition to this, over prolonged periods of time large sulfation crystals form on the negative plate reducing the battery’s active material (Figure 3). Once crystals have formed you cannot desulfate a battery. If left unmaintained, the net impact causes a rapid acceleration of battery aging and performance failures. By charging and cycling you can reduce the creation of crystals and the impact they have on the performance of the battery.

Temperature can also impact the physical damage done to batteries at low state of charge. High temperature causes loss of functionality and crystal formation creating shorts. When low temperature occurs, batteries in low states of charge are at a higher risk of freezing causing physical damage.

Much of this can be prevented with routine battery maintenance. Depending on where your (or your customer’s) batteries are “sitting” that could mean: keeping the battery connected to a trickle charger while in the garage, taking your vehicle for a 20-30 minute drive on a more routine basis, monitoring and charging the batteries of vehicles sitting on the lot, checking the state of health and charge of a customer’s vehicle battery regardless of the reason for the visit, or even just connecting a customer’s battery to a power supply during service. In the end, not letting the batteries sit dormant and unmonitored will ensure it works when needed most.

If you would like to better understand how this may impact you or your customers, feel free to send an email to your Midtronics account manager, and we’d love to help in any way possible.