Whether you’re a vehicle owner or a professional in the automotive repair industry, you’re fully aware of the importance of having a durable and reliable battery in any vehicle. And while car batteries might seem similar to one another, one popular type of battery that’s gaining popularity among manufacturers is the AGM (absorbed glass mat) battery.

They’re more readily available as a replacement from dealers and aftermarket suppliers as an ‘upgrade’ from the standard lead-acid battery vehicles are often equipped with. And more and more, OEMs are installing AGM car batteries from the factory, and for good reason.

In this blog post, we’ll take a detailed look at AGM batteries: their composition, their differences from other battery types, their applications, and the benefits and downsides of using AGM technology. We’ll also describe the key diagnostic and testing characteristics that you should consider when analyzing AGM batteries. So sit back, relax, and enjoy learning about AGM batteries with us.

How AGM Batteries Are Made

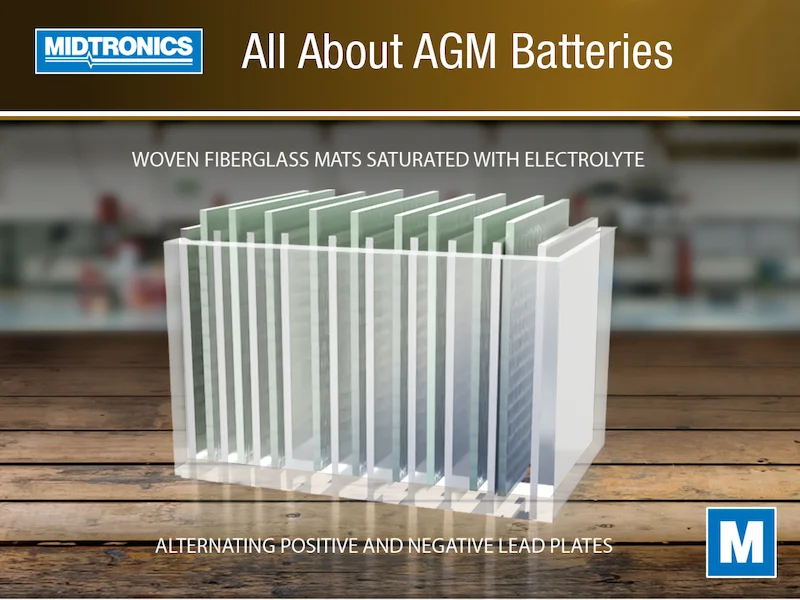

To understand AGM batteries better, it’s vital to delve into their manufacturing process. AGM batteries are made using a specialized process that involves glass mats, which are thin strips of woven fiberglass soaked in electrolyte. The resulting glass mat is then sandwiched between two lead plates, with the entire assembly being sealed to prevent acid leakage.

In AGM batteries, the glass mats serve various purposes, including acting as separators that keep the plates apart, ensuring optimum surface area contact and reducing internal resistance. Additionally, the glass mats help hold the electrolyte in place, thereby reducing the risk of leakage. This design creates a high-performing power source with excellent conductivity, long life, and resistance to deep cycling.

Differences from Standard Flooded Lead Acid Batteries

Compared to standard flooded lead-acid batteries, AGM batteries have several differences that make them a superior choice for many applications.

- AGM batteries have a higher charge acceptance rate, which means they can quickly recharge even after being discharged deeply.

- They have a lower self-discharge rate, meaning they can hold their charge for longer periods of unuse.

- AGM batteries have a long cycle lifespan, even when discharged deeply.

- Whereas a standard lead-acid battery’s lifespan is between three and five years, it’s common to get around six years of use from an AGM battery, and sometimes even more.

Applications for AGM Batteries

AGM batteries are perfect for a range of automotive applications, from powering cars, trucks, and buses, to aviation, marine, and renewable energy systems. With their ability to recharge quickly, AGM technology makes an excellent solution for auto start-stop systems and vehicles with high electrical needs.

They are also ideal for use in vehicles with complex electrical systems, such as those found in hybrid-electric and electric vehicles. In fact, most EVs have an AGM battery to power their 12-volt systems.

In addition to this, AGM batteries are perfect for use in off-road and recreational vehicles, such as ATVs, UTVs, and RVs. Their shock-resistant construction and low self-discharge rate make them perfect for use in equipment that is not frequently used but needs to function at peak performance when required.

Benefits of AGM Technology

AGM technology brings with it a range of benefits that make it an attractive choice for many applications. The following are some of the benefits that AGM batteries provide:

- Leak-proof – AGM batteries have a leak-proof design that ensures that electrolytes remain within the battery. This design makes it safe to use and transport the battery without worrying about spills that could cause severe damage to vehicles.

- High performance – AGM batteries deliver high performance even under heavy loads, making them ideal for use in vehicles with advanced electronics and power-hungry equipment.

- Deep cycle capability – AGM batteries can be discharged deeply without negatively impacting their lifespan, unlike other battery types.

- Maintained charge – The low self-discharge rate of AGM batteries allows them to maintain a charge for extended periods, making them an ideal power source for advanced automotive and heavy equipment.

- Versatile installation options – because they are more resistant to vibration and are leak-proof, AGM batteries can be used in applications where the battery isn’t able to be mounted upright.

Downsides of AGM Batteries

Like any other battery type, AGM batteries come with some downsides that must be considered before making a purchase. Here are some of the most significant downsides of AGM batteries:

- Cost – AGM batteries are more expensive than other battery types. The higher cost reflects the design and technology that goes into manufacturing them.

- Sensitivity to temperature – AGM batteries are sensitive to temperature changes, and extreme temperature changes can negatively impact their performance.

- Require full charge – You should always fully recharge an AGM battery between uses, so it might not be suitable in all applications.

Diagnostic and Testing Characteristics to Take Note Of

As well, AGM batteries are more sensitive when it comes to being charged. If they’re subject to high voltages or they’re overcharged, it can adversely affect the battery’s lifespan. Battery charging equipment should always specifically state that it’s capable of safely charging or maintaining an AGM battery, and those chargers typically include monitoring for voltage, amperage, and the ambient temperature.

As for battery testing, some older models or lesser-quality products could provide false readings with AGM batteries. Diagnostic equipment should also specify that it’s intended for AGM technology to get accurate readings that both the shop and the customers can trust. When you encounter AGM batteries, whether in a vehicle or as a potential replacement, know that they’re a high-quality option that can be suited for many different applications. However, they aren’t suitable for every application. And like standard lead-acid batteries, the key to longevity is regular testing and charging.