One of the most costly and challenging scenarios for fleet operations personnel is the dreaded call that a truck in the middle of a route will not start or the call from the service depot that the truck scheduled for the next delivery run will not start – all because of a bad battery. But both fleet vehicles were just fine the day before… Or were they?

No-Starts are typically unpredictable and occur without warning. These events are extraordinarily disruptive to the efficiency of fleet operations, which relies on maintaining schedule and timing. No-Starts that sideline a vehicle in route or just prior to scheduled route cost fleets enormous amounts in lost productivity, forfeited revenues, repair & service costs, replacement of damaged goods. All these directly impact the organizational bottom line, easily ranging from $900 – $1,700 per event. Perhaps worst of all, these disruptions in service are a real drag on Customer Satisfaction – who wants to have to explain to Customers their freight could not be delivered or picked up because a battery failed?

What if No-Start Events could be prevented?

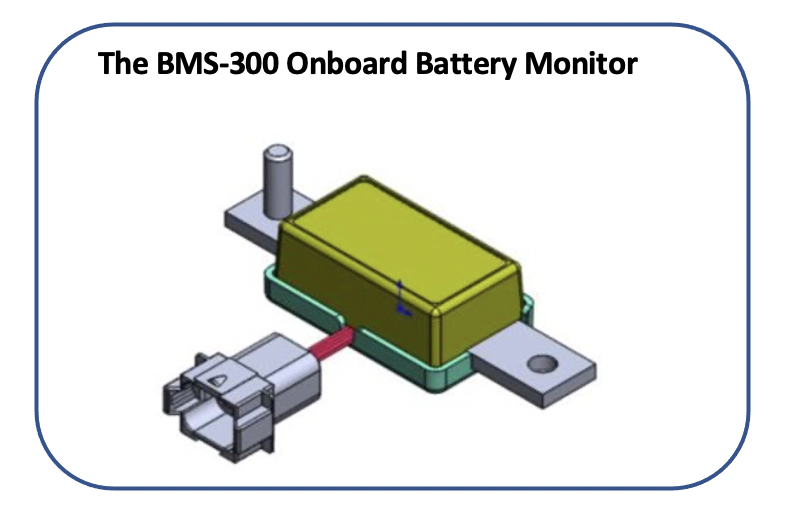

Midtronics has developed the BMS-300 onboard Battery Monitoring System which provides an early warning to fleet operations managers of a battery pack in one of the fleet vehicles that has entered a low state-of-health condition BEFORE it fails. The BMS-300 monitor communicates directly with the truck telematics system or sends messages via the truck’s CAN bus network and signals batteries that need further diagnostics prior to failing.

The BMS-300 captures battery data in real-time, runs algorithms, and communicates the information via the truck’s CAN bus. The monitor measures battery voltage and current draw and is specifically engineered to monitor state of charge. Because it can also measure current, it provides insight into load usage and parasitic draw that are otherwise very hard to detect. The BMS-300 sensor can capture 1,000 voltage and current measurements per second at the battery pack, but it reports only the important info through CAN. The BMS-300 can measure starting currents up to 3,000 amps. As a result, it can report the lowest voltage and the inrush current during every start event. It’s like doing a starting system test every time the engine is started.

BMS-300 Features:

- Single device mounts to one battery or a bank of batteries

- Measures voltage, current, and temperature

- Measures amp-hours of energy going into and out of the batteries

- Calculates conductance (CCA) of battery, starting, and charging system

- Calculates starting capability of the batteries

- Provides warning of low state of charge or poor state of health of batteries

- Reports CAN J1939 messages via direct wiring to a sealed connector

Keeping trucks on routes and on schedule is a key to managing your organization’s operational costs and profitability, as well as maintaining great customer relationships in a very competitive environment. Midtronics’ breakthrough battery health monitoring technology will definitely add to your bottom line and improve your fleet uptime. Click the link to learn more about Midtronics’ BMS-300 Battery Monitoring System. We can guide you through a very simple ROI calculator on the impacts of outfitting your fleet with an onboard early warning battery monitor.

To discuss your specific needs/application, click the button below to fill out the form or email John Philbrook at jphilbrook@midtronics.com.