In today’s automotive industry, battery testing has become even more important for reliable vehicle performance. From hybrid and EV models to traditional combustion engines, battery health is central to ensuring vehicles operate smoothly. But when it comes to diagnosing battery issues, not all testing methods are created equal. There’s a notable difference between in-vehicle battery testing, often performed at dealerships and repair shops, and bench testing, commonly offered at parts stores.

This article explores the pros and cons of each method and highlights why in-vehicle testing stands out as the superior choice.

Ins and Outs of In-Vehicle Battery Testing

In-vehicle battery testing evaluates the battery’s health while it remains installed in the car, as the name indicates, assessing how it performs in the vehicle’s electrical system. This type of testing provides a more complete look at battery performance under real conditions. The benefit? A realistic look at how the battery functions under typical operating conditions.

The primary advantage of in-vehicle testing is its accuracy. By assessing the battery in the full context of the vehicle’s systems including charging and starting, technicians can see how the battery relates with other components and identify any potential faults. This approach also allows service departments to diagnose and address a broader range of issues beyond battery health, offering a more comprehensive solution than a standalone battery test.

What Bench Battery Testing is All About

Bench testing, commonly what you’re offered at parts stores, involves removing the battery from the vehicle and testing it – quite literally – on the workbench. Bench testing tools measure aspects like voltage and resistance to determine if the battery can hold a charge. While this method can quickly identify if the battery has obvious issues, it doesn’t account for the battery’s performance in relation to the vehicle’s electrical system.

Bench testing offers a narrow scope of information, as it only measures the battery itself and ignores other systems altogether. Without context, bench testing may miss issues or fail to detect how the battery’s performance is affected by the alternator, starter, or other systems. For a quick evaluation, bench testing may suffice, but it often lacks depth that service shops provide.

Pros of In-Vehicle Battery Testing

More Accurate Diagnosis

In-vehicle testing provides an in-depth look at the broader electrical scope. This real-time assessment can reveal issues with the battery, or other components like the alternator. For example, if a customer’s vehicle has a dead battery often, in-vehicle testing can help pinpoint whether the battery is truly at fault or if the alternator is failing to charge it properly.

Improved Customer Satisfaction

In-vehicle testing often leads to higher customer satisfaction by providing fast, accurate results. Rather than receiving a simple pass or fail, customers are given a full summary that explains the battery health and any related systems. Transparency not only saves time but also builds trust – customers feel confident in the service they receive.

Increased Sales Opportunities for Repairs

Another key advantage is the ability to identify and recommend additional repairs. When technicians can pinpoint issues beyond the battery itself such as alternator or starter problems, it opens up opportunities to discuss maintenance or repairs. It often leads to a more proactive approach to vehicle care, benefiting both the customer and the shop.

Pros of Bench Testing in Parts Stores

Convenience for DIY Customers

Bench testing has its place, especially for DIY customers looking for a quick and convenient option. Many parts stores offer free battery testing, making it an easy option for customers who may want to evaluate their battery before making a purchase or performing a replacement on their own.

Lower Immediate Cost

Since bench testing is often provided as a complimentary service, it attracts customers looking to save on labor charges. While it may lack the depth and accuracy of in-vehicle testing, bench testing serves as a fast, no-cost way for customers to identify whether their battery might need a replacement.

Cons of Bench Testing

Not as Thorough

Bench testing’s greatest limitation is that it can’t diagnose issues within the broader electrical system. Since the battery is tested in isolation, it doesn’t factor in the charging system, starter, or other parts that may be affecting battery health. In-vehicle testing provides a more comprehensive analysis, catching potential issues bench testing could easily miss, saving customers from further repairs and frustration.

Missed Opportunities

Because bench testing only evaluates the battery, warning signs related to other systems often go unnoticed. Technicians in repair shops can examine the battery’s interaction with the rest of the vehicle’s systems, enabling them to recommend services or repairs that may prevent more serious issues down the road.

Potential for Inaccurate Results

Bench testing can yield false positives or negatives. Factors like temperature, voltage loads, and battery age can alter test results. On the other hand, in-vehicle testing delivers accurate data on how the battery functions in real-world conditions, lowering the chances of a misdiagnosis.

How Dealerships and Repair Shops Benefit from In-Vehicle Testing

Enhanced Customer Trust and Retention

When customers experience transparent and thorough testing, especially in their presence, they’re more likely to trust the service provider. By performing in-vehicle testing, repair shops position themselves as reliable and professional. This approach also boosts customer retention, as clients are more inclined to return for service when they feel they’ve received accurate, trustworthy help.

Opportunities to Educate Customers

In-vehicle testing allows you to share real-time data with customers, showing them exactly how the battery is performing without it being anecdotal only. This is a valuable opportunity to educate customers on why certain repairs may be necessary, and how the battery and electrical system interact. An informed customer is more likely to approve necessary repairs, making this a win-win.

Wrapping Up

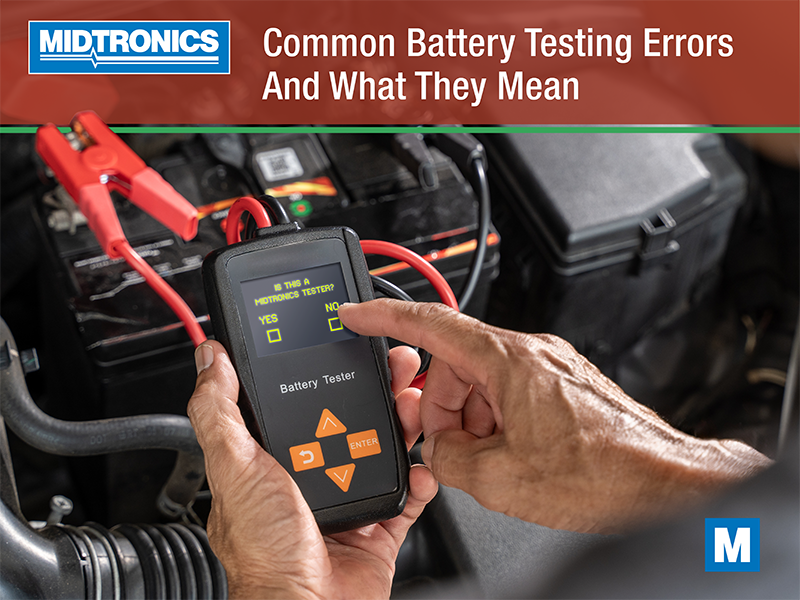

In-vehicle testing offers clear advantages for both customers and shops. While bench testing may be convenient for DIY customers, it’s a less effective option. Dealerships and repair shops using in-vehicle testing tools like those from Midtronics, can provide a fuller picture of battery health, revealing not only its current condition but also any other underlying issues.

In-vehicle battery testing doesn’t just save time and money on repairs – it builds trust and satisfaction, helping customers feel confident about their vehicle’s overall health. For dealerships and repair shops, explaining this service to customers can be a valuable way to differentiate from parts stores and build a reputation as a go-to source for reliable vehicle care.