Staying on the cutting edge of technology helps to meet customer demands, and for the automotive industry, spiral cell batteries are one of those advancements. They’re extremely recognizable by the six-pack design.

As leaders in the automotive industry, understanding the value proposition of spiral cell batteries can be a game-changer for business. Not only do these batteries offer higher performance, but their maintenance-free and safer design can lead to increased customer satisfaction and repeat business. Learn more about what spiral cell technology is all about.

What’s Unique About Spiral Cell Battery Technology?

Spiral cell technology, a subset of AGM) batteries, is a unique design using tested and true practices. The name ‘spiral cell’ stems from the physical layout of the battery, where lead plates are meticulously wound into a spiral or coiled configuration.

In a spiral cell battery, two lead plates – one positive and one negative – are wound in a tight spiral design. These spirals are separated by an absorbent glass mat (AGM). This mat is made from very thin glass fibers woven into a mat, which increases surface area to hold sufficient electrolytes on the cells and for the chemical reaction. The AGM also serves as a physical barrier between the positive and negative plates, preventing a short circuit.

The spiral-wound construction gives the battery a cylindrical cell, similar to a common flashlight battery. This design stands in stark contrast to traditional flat-plate batteries that have a rectangular grid of lead plates.

The electrolyte in these batteries is absorbed by the AGM, giving these batteries their ‘starved electrolyte’ condition. This means the electrolyte is confined to the mat and cannot spill or leak, making these batteries safer and maintenance-free.

The spiral winding provides a larger surface area of active material (lead dioxide and sponge lead) in contact with the electrolyte compared to traditional batteries. This leads to higher power density, meaning more power can be delivered in a shorter time frame.

Furthermore, the tightly wound plates give the battery a more robust structure, making it highly resistant to the common problem of vibration damage in standard lead-acid batteries. This strength makes spiral cell batteries ideal for tough conditions such as off-road applications or marine use.

Spiral Cell Batteries vs. Traditional Lead-Acid Batteries

Compared to traditional flat plate lead-acid batteries, spiral cell batteries offer several advantages.

- First, they are more resistant to vibration and shock, making them durable and long-lasting.

- Secondly, they can provide higher power outputs for their size due to the increased surface area of the lead plates.

- Lastly, their sealed construction makes them maintenance-free and safer to use, as there’s no risk of acid leakage.

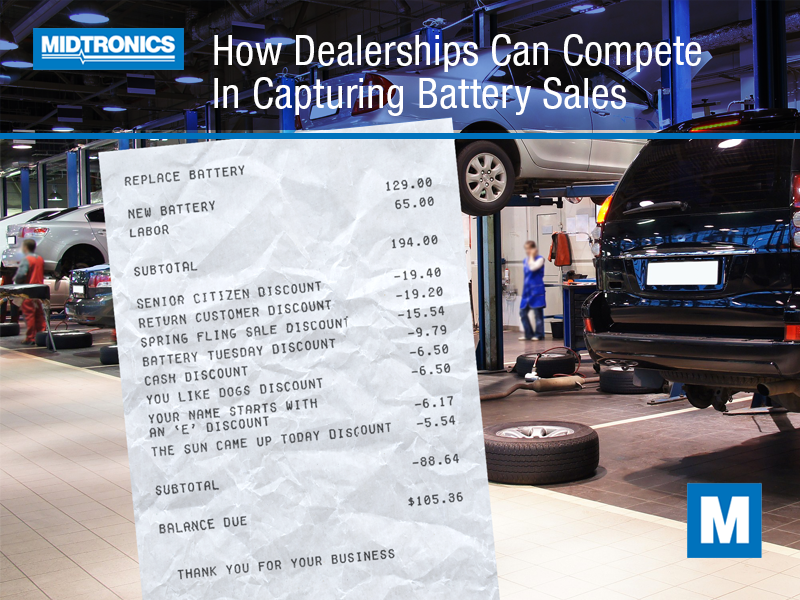

But as any advanced technology goes, there’s a higher cost to pay for spiral cell batteries. Replacement costs are roughly two to three times that of a traditional SLA battery. Some vehicles that can reliably operate with a common SLA battery might not see any added benefits from upgrading to spiral cell, particularly when they are older models or their electrical demands are relatively low. One benchmark is that if a vehicle’s factory-equipped battery isn’t an EFB or AGM battery, then under ordinary use, you probably won’t notice a difference.

Spiral Cell Battery Applications

Spiral cell batteries have a wide range of applications due to their robustness, high power density, and maintenance-free design. Here are some areas where they are used:

- Automotive industry. Spiral cell batteries are ideal for vehicles that require high starting power. They deliver quick bursts of energy to start the engine and then recharge quickly. Their resistance to vibration also makes them suitable for off-road vehicles and heavy-duty equipment that undergo rough handling.

- Marine. Boats and marine equipment need batteries that can withstand harsh conditions and frequent vibrations. Spiral cell batteries’ leak-proof design and strong structure make them ideal for this environment. Plus, their ability to deliver high power in short bursts is perfect for starting boat engines.

- Recreational Vehicles. RVs often need reliable power for both starting the engine and running onboard appliances. The power density of spiral cell batteries makes them well-suited to these dual requirements. Also, their maintenance-free design is a boon for travelers who don’t want to worry about battery upkeep on the road.

- Uninterruptible Power Supply (UPS) Systems. UPS systems require batteries that can provide instant power in the event of a power outage. The power output and quick recharge time of spiral cell batteries are crucial in these scenarios.

- Solar power. In solar setups, batteries need to store energy efficiently and discharge it reliably when needed. Spiral cell batteries excel in this area due to their high energy density and efficiency.

- Emergency vehicles. Police cars, ambulances, and fire trucks need reliable and high-performing batteries. Their high power output and quick recharge capability make them ideal for these critical vehicles.

In general, spiral cell batteries are a great choice for applications requiring above normal power output, quick recharging, and a robust, maintenance-free design.

How to Charge a Spiral Cell Battery

When it comes to charging, spiral cell batteries require a specific approach. They need a higher voltage compared to regular lead-acid batteries. Also, they should not be overcharged as this can lead to excessive heat and damage the battery.

It’s recommended to use a charger designed specifically for use on AGM batteries. What’s most important about charging is that the charging profile that’s used stays within certain limits that the battery manufacturer specifies, such as keeping the maximum voltage under a certain level and ensuring the battery temperature doesn’t increase to the point where it begins to offgas. Low and slow tends to be best.

Testing Spiral Cell Batteries

Fortunately, testing spiral cell batteries doesn’t require any technology beyond what shops are commonly equipped with. As long as the diagnostic equipment supports AGM batteries, it should be sufficient to test this type as well.

If the battery is unable to hold a charge or can’t be fully recharged, it’s time to recommend a replacement. Any test result that returns as “Replace Battery” should be changed to avoid situations that would leave the car owner stranded and unhappy.

Spiral cell batteries represent a significant advancement in battery technology. Their robust design, high power output, and maintenance-free operation make them a superior choice for high-demand applications. However, they require careful charging and regular testing to keep them in peak condition. Despite their higher upfront cost, the benefits they offer can outweigh the investment, but they aren’t always as beneficial for vehicles with lower electrical needs.